Contemporary Material and Technological Culture

3D Printed Shading System

This research develops a 3D-printed shading façade inspired by desert dunes and traditional Arab screens, optimised through computational design and material testing for lightweight, modular, and identity-driven temporary architecture.

.jpg)

Summary

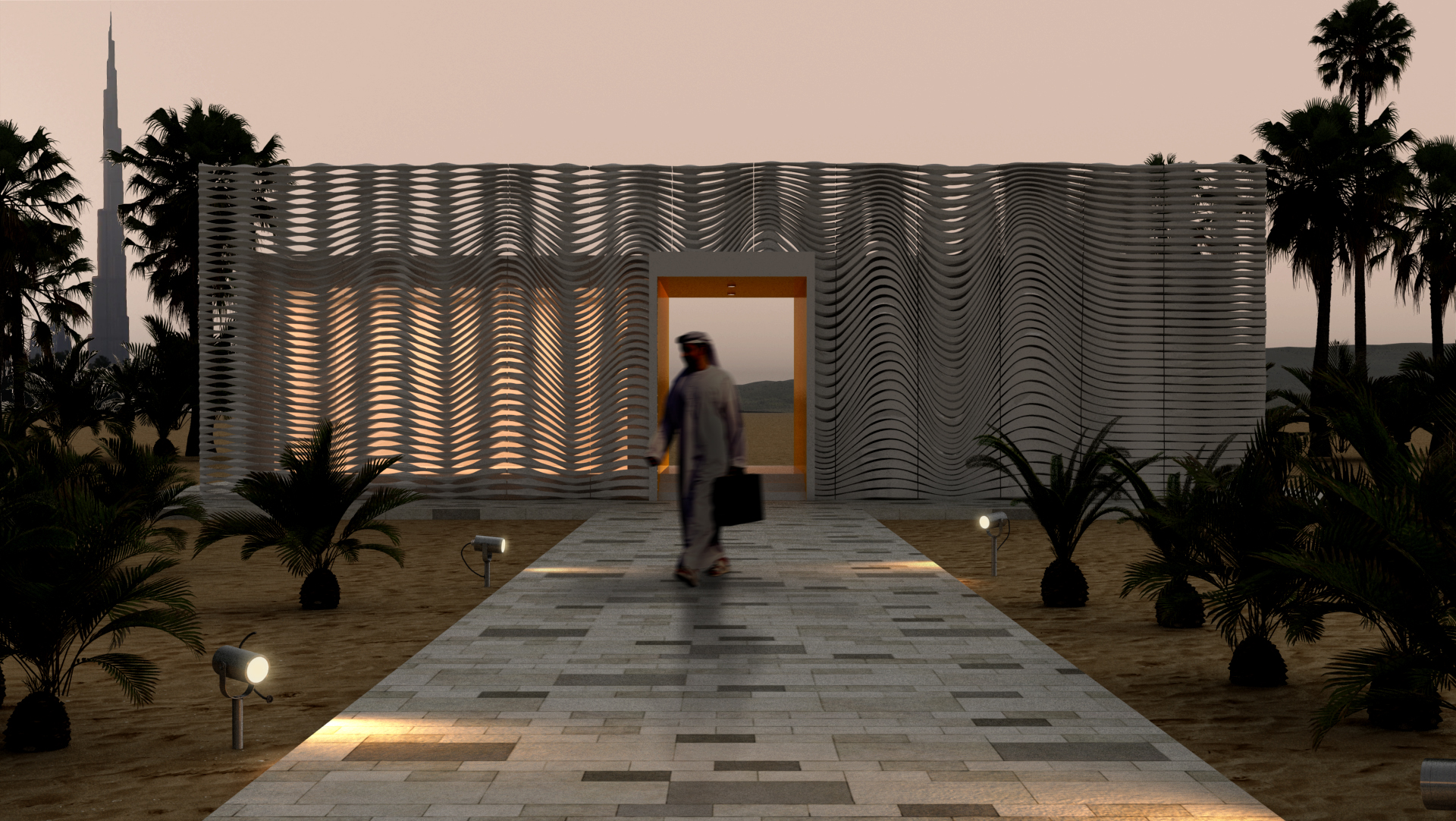

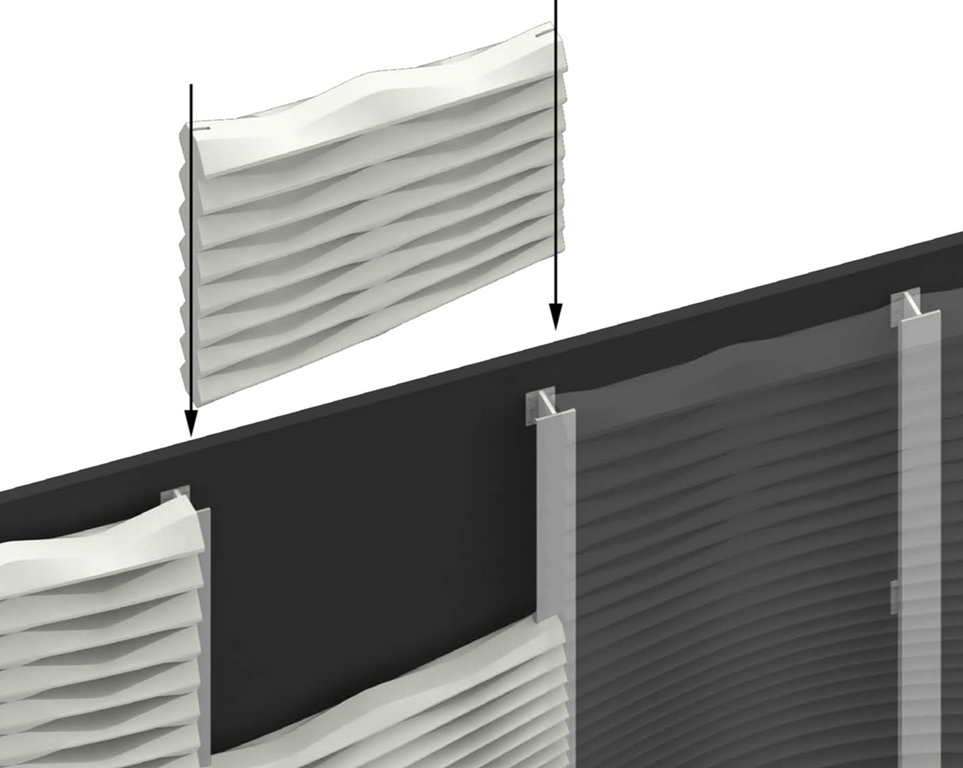

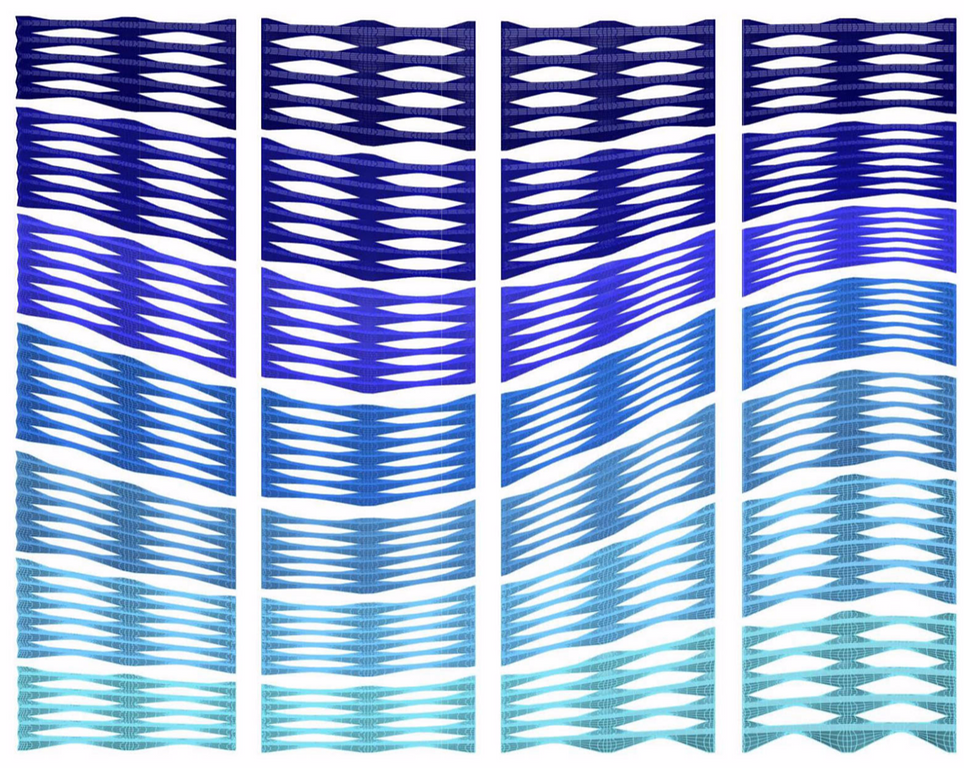

The project presents a 3D-printed façade system designed for a service pavilion at Expo 2020 Dubai, with potential for replication in other temporary or overlay structures. Responding to Expo requirements—lightness, modularity, flexibility, and cultural identity—the façade draws inspiration from local desert winds and ornamental screens used for shading and privacy. Using computational design algorithms, the system defines a pattern of variable porosity, curvature, and thickness, optimised for additive manufacturing. Extensive material and climatic testing was conducted at Politecnico di Milano to ensure high-temperature performance. The research combines digital aesthetics, fabrication efficiency, and cultural narrative in a scalable design solution.

Examines flexible and decentralized production systems that support customization through digital design and adaptive manufacturing. The main concepts of mass customisation, supply chain management and distributed manufacturing are linked together to optimize material use, environmental impact and prefabrication in architectural design.|