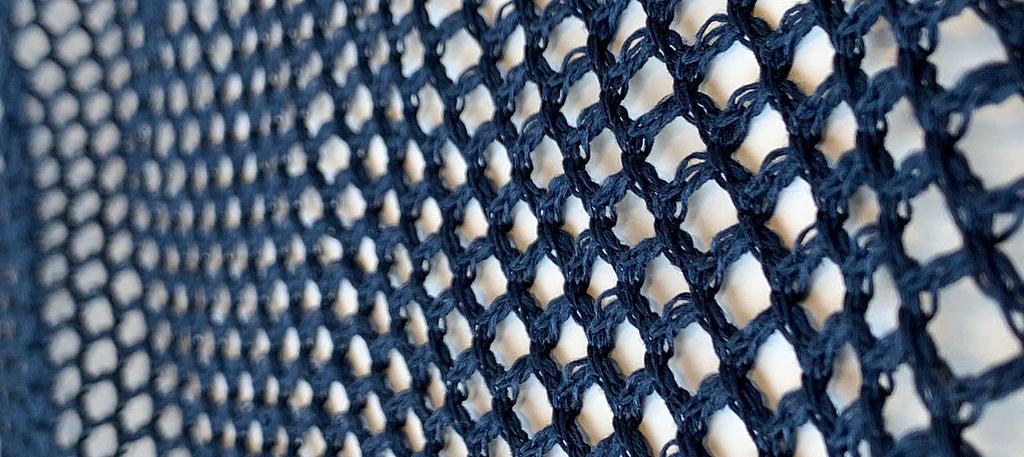

This research examines how knitting technologies, traditionally employed in fashion, can be repurposed for large-scale architectural applications. Textiles are increasingly recognised as vital materials in contemporary architecture, enabling the construction of lightweight, geometrically complex structures that influence environmental performance—from light diffusion and air permeability to acoustic insulation and structural flexibility.

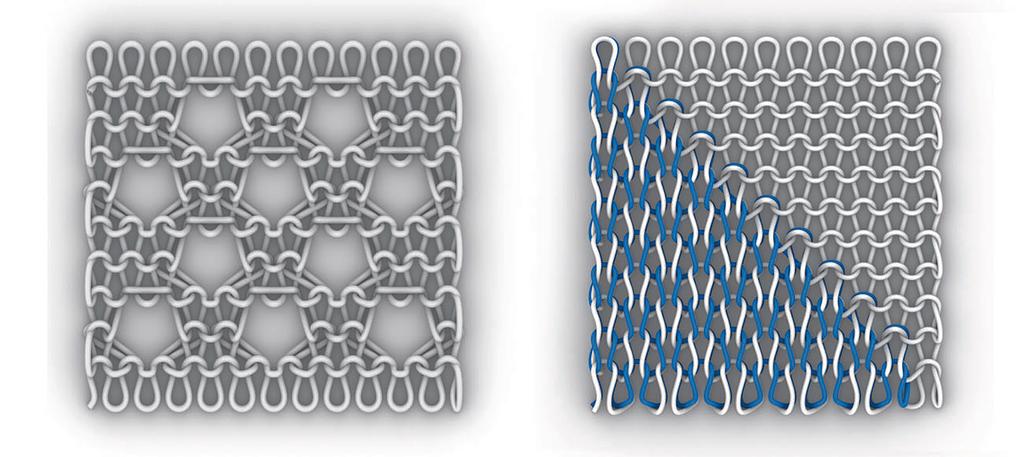

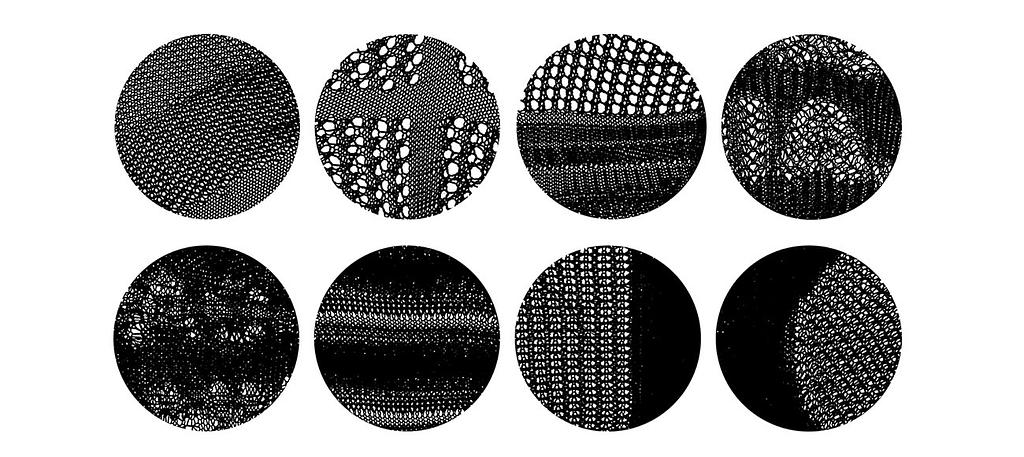

At the core of this investigation is the idea of designing textiles with non-homogeneous composition, where fibre density and strength vary across the surface, concentrating material only where it’s needed. This approach significantly reduces weight and resource use while maintaining high structural and environmental performance.

Traditionally, textile production for architecture involves multiple wasteful steps—patterning, sewing, and welding—that increase both time and cost. By contrast, modern CNC knitting machines can produce seamless, three-dimensional textiles directly from digital models, with minimal human intervention and virtually zero material waste. However, programming these machines remains complex and labour-intensive, typically requiring expert “knitting engineers” and relying on trial-and-error methods. This makes large-scale, bespoke textile production inefficient and costly.

Our research introduces a computational design workflow that automates the creation of architectural textiles by integrating CNC knitting technologies with parametric design tools, such as Rhinoceros and Grasshopper, and simulation plug-ins for physical behaviour. This integration enables the creation of textiles that are not only custom-shaped and structurally optimised but also responsive to environmental data.

By shifting from manual to automated programming, Computational Knitting proposes a new paradigm in textile fabrication—one that is fast, adaptive, sustainable, and suitable for architectural use. The system offers a promising alternative to traditional construction materials and even 3D printing, particularly in contexts that require bespoke, flexible, and high-performance components.

This work envisions a future where architectural surfaces are woven rather than assembled—where structure, comfort, and performance emerge from the logic of threads.

SCIENTIFIC COORDINATOR

Maria Anishchenko - PhD Candidate

SENSEKNIT PROJECT

Exposed at MADE EXPO 2019, Milano design week 2019, Tensinet Symposeum 2019

CLOUDLAND WORKSHOP

Workshop and installation for Triennale di Milano

PARTNERS

Adidas; Sinterama; Artemaglia